A wearable, flexible X-ray detector that is constructed without using harmful heavy metals has been developed by researchers from China and the US. The prototype, which is made from metal–organic frameworks layered with gold electrodes and plastic, could provide a safer and more environmentally friendly route to the next generation of radiology devices.

Conventional radiation detectors for X-ray imaging – whether integrated into large, immobile instruments like CT scanners or the small bitewing detectors used by dentists – are typically fashioned into rigid panels. For some applications, however, flexible sensors would be more appropriate, for example in allowing detectors to conform to rounded body parts or to be moulded into the inside of confined spaces. To this end, researchers have turned to so-called metal–organic frameworks – flexible, semiconducting materials that respond to electromagnetic radiation by producing a measurable electric current.

Unfortunately, however, many of these metal–organic frameworks have a drawback that they share with conventional, rigid X-ray detectors: they are partly made from lead, the mining and use of which brings both environmental and health risks.

“Although the encapsulated detectors present a low risk of exposure to patients, there is a significant health risk to the manufacturing and maintenance personnel involved,” explains mechanical engineer Shenqiang Ren of the State University of New York at Buffalo.

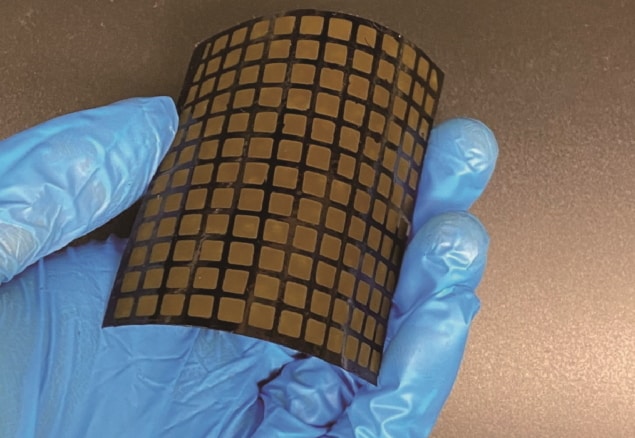

In their study, Ren and colleagues produced a lead-free metal–organic framework by mixing a nickel chloride salt with 2,5-diaminobenzene-1,4-dithiol (DABDT) for several hours. The nickel linked the DABDT molecules, resulting in a compound that was more sensitive to 20 keV X-rays (suitable for use in diagnostic imaging applications) than recently reported flexible detectors made from amorphous selenium, Cs2TeI6 or gallium(III) trioxide. To make a basic sensor array, the team sandwiched individual pixels of their metal–organic framework between gold electrodes before attaching each to a plastic surface and linking them up with copper wiring. Finally, they coated the whole device in a flexible, silicone-based polymer.

Proof-of-concept

Tests imaging an aluminium letter “H” placed on the detector array confirmed that a significantly lower current output was recorded by the pixels covered by the metal shape than those that were unimpeded. The detector, Ren says, “manifests a high detection sensitivity and low detection limit, demonstrating a proof-of-concept wearable X-ray detector for radiation monitoring and imaging”.

While the researchers’ prototype featured only a 12 x 12 grid – and measured 6 x 6 cm – the design is inherently scalable to both higher resolutions and pixel densities. “Traditional X-ray imagers are rigid and uncomfortable to wear on the body or to place near the examined organ,” Ren explains. “The flexible detector shown in this work could be mounted onto objects with curved geometries and complex surfaces, such as wearable electronics.” Alongside applications for medical imaging, the flexible sensor could also be used for dosimetry measurements and for non-destructive object scanning.

“The need to implement large area, low-power operated and conformable radiation detectors has recently triggered a quest for novel material platforms able to reliably detect ionizing radiation,” comments Beatrice Fraboni, a physicist from the University of Bologna, Italy, who was not involved in the present study. The metal–organic framework developed by Ren and colleagues, she adds, is a “novel and promising candidate that well compares with the other material platforms so far proposed for this task – organic semiconductors and perovskites – and grants a lead-free, and thus sustainable, option”.

Flexible detector takes high-resolution X-ray images in 3D

Imalka Jayawardena – an engineer from the University of Surrey who was also not involved in the study – agrees, noting that metal–organic frameworks have also shown promise in other areas, including photodetection and energy storage. “This work certainly shows the potential of such material systems for future X-ray detector technologies that should not only have high sensitivity but can also curved to conform to complex geometries,” he says.

With their initial study complete, the researchers are now moving to explore the structural design and controlled sensing performance of a variety of different metal–organic frameworks, alongside improving the resolution of their detector design and exploring the potential for large-scale manufacturing.

The study is described in Nano Letters.