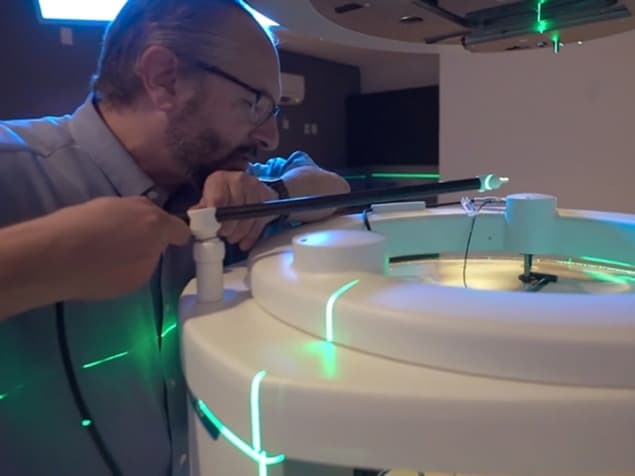

The SunSCAN 3D cylindrical water tank helps medical physics teams work smarter when commissioning their radiotherapy systems and carrying out annual machine QA checks

Faster, easier, hyper-accurate: these are the key benefits of the new SunSCAN 3D Cylindrical Water Scanning System from Sun Nuclear Corporation, a US-based manufacturer of QA solutions for radiotherapy and diagnostic imaging providers. Think faster and easier workflows for medical physicists tasked with beam commissioning and annual and biannual machine QA. Think hyper-accurate dosimetry for the growing demands of stereotactic radiosurgery (SRS) and stereotactic body radiotherapy (SBRT). Think granular beam data and beam model visualizations to ensure the treatment machine is calibrated accurately while also guaranteeing “gold-standard” verification of the delivered dose applied to the patient.

Automation means reproducibility

Building on the capabilities of Sun Nuclear’s 3D SCANNER water tank, with over 1000 systems in use worldwide, the SunSCAN 3D was formally unveiled to the market last month at the ESTRO annual congress in Copenhagen, Denmark.

“Feedback from delegates was phenomenal – whether from existing users of our 3D SCANNER or prospective new customers,” explains Julia Kirchhefer, a medical applications physicist at Sun Nuclear. “SunSCAN 3D’s automated set-up was one of the main conversation topics on the booth,” she adds, “not least with ESTRO attendees accustomed to manual preparation of their water tanks – a time-consuming exercise that can take up to an hour.”

With SunSCAN 3D, form, function and automation come together to make the medical physicist’s job easier to do. Specifically, the AutoSetup routine takes about seven minutes to provide a truly levelled water tank (to within 0.05° and centred within 0.1 mm). AutoSetup is in fact a stepped process comprising Auto Level (three widely set points quantify tank “levelness” with a repeat measurement to confirm set-up); Auto Centre (using profile measurements, fine adjustments in the x and y direction align the centre of the SunSCAN 3D with the beam centre); and Auto Angle Offset (for alignment of the ring centre and angular orientation to the collimator axis).

Crucially, the whole SunSCAN 3D workflow is automated to guarantee a fast and reproducible tank set-up that is independent of the user’s experience. “You could have three different people set up the tank and it will be in the exact same spot each time,” adds Kirchhefer. “Alongside the built-in workflow efficiencies, that also means a significantly reduced training overhead.” Underpinning it all, the SunSCAN 3D delivers exceptional scanning performance for SRS/SBRT treatments, with a coordinate measuring machine to verify 0.1 mm accuracy throughout the tank, 0.05 mm reproducibility and 0.02 mm resolution.

Intuitive innovation

Meanwhile, the benefits of SunSCAN 3D’s unique cylindrical design are also front-and-centre in the treatment room. Operational streamlining is again one of the main drivers here, with the cylindrical design removing the need for time-consuming tank shifts that can adversely impact data quality (see “User-centric cylindrical design”). “The physicist can use the full diameter of the tank as the scanning range – there’s no need for tank shifts,” notes Kirchhefer. The cylindrical geometry also ensures consistent detector orientation, with the ability to rotate the tank by 360° such that the smallest dimension of chamber always measures beam edge for the sharpest penumbra.

Reinforcing the granular emphasis on workflow efficiency is SunSCAN 3D’s SunDOSE software, an intuitive “fewer clicks” interface that’s intended to make machine commissioning and QA easier than ever. “With SunDOSE, it’s straightforward to perform tank set-up and collect and store data in the SQL database to meet the unique needs of the medical physics team,” explains Kirchhefer. “What’s more, the comparison of scans from annual checks or commissioning is quick and easy – taking just a couple of minutes – as every scan is tagged versus energy, field size and scan type.”

Spreading the word

Going forward, the priority for Kirchhefer and her Sun Nuclear colleagues is to get the SunSCAN 3D in front of clinical customers at scale. After debuting the system at the ESTRO annual congress, the system was subsequently showcased at the annual meeting of the Germany Society of Radiation Oncology (DEGRO) and the World Congress on Medical Physics and Biomedical Engineering.

SunSCAN 3D will also be featured at the AAPM and ASTRO annual meetings in the US later this year, as well as the European Congress of Medical Physics in Dublin, Ireland, and the Annual Conference of the German Society of Medical Physics (DGMP) in Aachen, Germany. “In parallel, we’ll be taking the SunSCAN 3D direct to the clinics,” concludes Kirchhefer, “with roadshows in the works for Germany, the UK, Italy and France over the summer.”

- For further information about the SunSCAN 3D Cylindrical Water Scanning System, register now for Sun Nuclear’s SunSCAN 3D webinar series.

User-centric cylindrical design

With square 3D water tanks, it is not possible to measure a full 40×40 cm field at 30 cm depth and 100 cm source-to-surface distance (SSD) unless the user shifts the water tank twice, making two measurements of two “halves” of the beam at different tank locations. This technique is inherently time-intensive and can introduce errors that compromise data quality.

In contrast, the cylindrical shape of the SunSCAN 3D enables the most efficient scanning ranges. For example, a 65 cm scan range is possible without a shift, allowing a 40×40 cm measurement at 30 cm depth and 100 cm SSD – saving time and eliminating potential errors. The 65 cm scan range is achieved with the offset detector holder, whereby two scans are merged without the need for a tank shift.