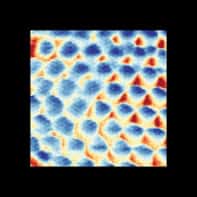

Batteries based on zinc are promising alternatives to their widely-used lithium-ion cousins, but they suffer from one of the same drawbacks: needle-like structures called dendrites that form on the surface of the electrode and grow into the electrolyte, ultimately causing the battery to short or even ignite. Researchers led by Quan-Hong Yang of Tianjin University, China, have now developed a partial remedy in the form of an organic electrolyte made from a widely-used industrial salt and an ethylene glycol solvent. Together, these materials form a protective layer that guards the zinc electrode against dendrite growth.

While lithium-ion batteries are today’s battery of choice in portable electronics and electric vehicles, the flammable and toxic organic electrolytes they contain are a cause for concern. Lithium is also expensive relative to some other, more common metals, and the global supply is subject to various uncertainties. Zinc batteries, which are normally formed with aqueous electrolytes, are an attractive substitute because zinc is cheaper, less toxic, more easily recycled and more widely available than lithium. They also have a high energy density, with a high specific capacity (820 mAh/g and 5,855 mAh/cm3) and a favourable redox potential (−0.76V versus the standard hydrogen electrode) of the Zn anode.

Implementing zinc technology is not all plain sailing, however, and there are some major technical barriers to overcome. One of these is the aforementioned dendrite growth. Another is the material’s tendency to undergo side reactions such as hydrogen evolution and corrosion with water. These side reactions jeopardize the batteries’ cycling stability and shorten their lifetime, respectively, by continuously consuming both the electrolyte and the zinc anode.

The fundamental cause of these problems is the interaction between the metallic zinc anode and the aqueous electrolyte. One way to avoid them is to use electrolytes that do not contain any water. Such electrolytes are expensive, do not conduct ions well, and can even be hazardous. Researchers are thus looking for alternative strategies to protect zinc anodes from water.

A new suppression strategy

The salt that Yang and colleagues used, zinc tetrafluoroborate hydrate (Zn(BF4)2), has rarely been employed in batteries. It does, however, have prominent applications in electroplating and textile manufacturing, where it acts as a flame retardant. By coupling this salt with ethylene glycol (EG) – a material that is, incidentally, cheaper than conventional ZnSO4 electrolytes – the researchers were able to promote the formation of a protective ZnF2 passivating layer that suppresses side reactions as well as inhibiting the growth of zinc dendrites.

Beyond the lithium-ion battery

The resulting hydrous Zn(BF4)2/EG electrolyte is non-flammable and works over a wide temperature range, from –30°C to 40°C. The electrode can be cycled for over 4000 hours at a current density of 0.5 mA/cm2 with a high Coulombic efficiency of 99.4%. Based on these figures, Yang says the new electrolyte shows much promise for developing Zn batteries that are safe, high-performance and sustainable. “We now plan to improve our device and also explore more electrolyte formulations to promote the rapid practical use of such batteries,” he tells Physics World.

Full details of the new electrode are reported in Nature Sustainability.