The THALES 3D MR SCANNER from LAP is helping medical physicists to fast-track QA test routines on their MR-guided radiotherapy systems, while a new iteration of the phantom delivers similar workflow efficiencies on bore-type linacs

Following the full product launch in the spring of last year, the THALES 3D MR SCANNER has emerged as something of a game-changer in the radiation oncology clinic, providing a “gold-standard dose accuracy check” for medical physics teams tasked with overseeing the acceptance and ongoing verification of the new generation of MR-guided radiotherapy (MR/RT) systems.

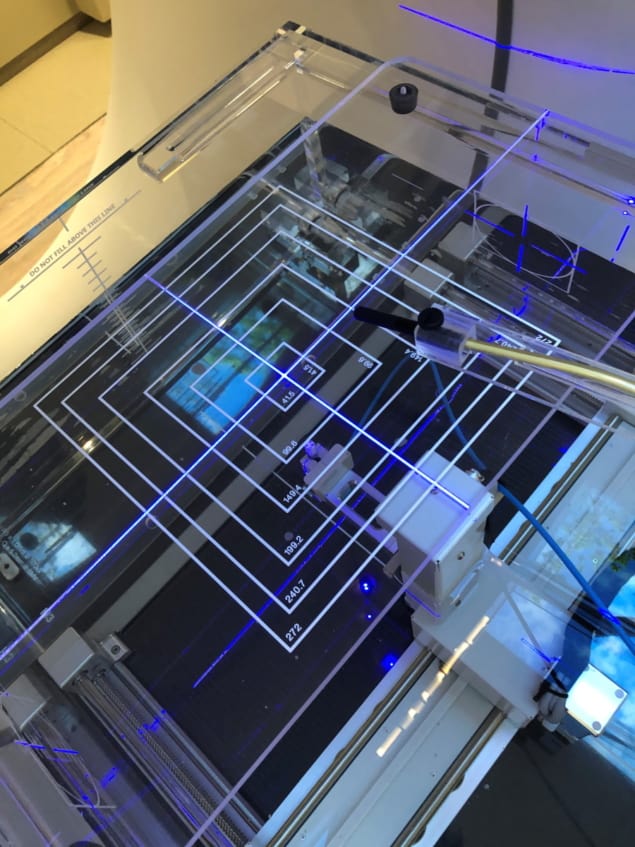

Developed by laser and radiotherapy QA specialist LAP, the THALES 3D MR SCANNER provides the radiotherapy physicist with a 3D and MR-compatible motorized water phantom that’s tailored specifically for streamlined commissioning and QA of MR-Linac treatment machines. By necessity, the phantom is MR-conditional – i.e. all system components are made from non-ferromagnetic materials certified for use within the MRI scanner’s magnetic field – while the automated set-up (which takes under 15 minutes to prepare) and predefined measurement sequences are intended to help the medical physics team save time and simplify their test routines.

“It’s still early days, but we’re really encouraged by the clinical response and uptake of the THALES 3D MR SCANNER within the MR/RT user community,” explains Thierry Mertens, a physicist himself and LAP’s business development manager for healthcare.

Prioritizing workflow efficiency

Commercially, too, there’s no shortage of momentum for LAP’s new water phantom. Significant milestones ticked off in the first quarter of 2021 include 510(k) regulatory approval from the US Food and Drug Administration (FDA), while the subsequent CE mark has enabled LAP to ramp up installations with clinical customers in the European Economic Area (EEA). In both regions, the phantom comes with a yearly maintenance visit, software and hardware updates, and a configurable multiyear warranty.

The traction with early-adopting clinical sites in the US and EEA is doubly important. After all, it’s feedback from these customers that will shape the development roadmap for the THALES 3D MR SCANNER in 2022 and beyond. Near term, it seems, product innovation is rooted in LAP’s relentless focus on workflow efficiency. “We are enhancing the phantom’s software functionality with this in mind – and specifically the introduction of a continuous scanning mode,” notes Mertens. “In this way, radiotherapy physicists will be able to spend less time on their machine QA so that they can focus on other important tasks.”

While the initial version of the phantom is optimized for the QA of ViewRay’s MRIdian MR/RT system, Mertens and colleagues are working on a custom water phantom to support Elekta’s Unity MR-Linac machine. The development work is already advanced, with LAP’s product development engineers in collective exchange with Elekta Unity clinical end-users. “The voice of the radiotherapy clinical user is fundamental to our requirements-gathering and for understanding – at a granular level – how the MR-Linac is being put to work in a clinical context,” Mertens adds.

Independent verification

At the clinical sharp-end, of course, it’s the medical physicist who is ultimately accountable for safe and effective MR/RT treatment delivery. This is where independent QA and verification tools – like the THALES 3D MR SCANNER – really come into their own, providing rigorous beam data and beam model visualizations to verify that the delivered radiation as it applies to the patient is indeed correct.

Operationally, the THALES 3D MR SCANNER is being deployed alongside a portfolio of QA tools – some providing daily, weekly and monthly QA checks, with the water phantom reserved for system commissioning and ongoing verification of dose delivery after any major upgrades to the MR-Linac hardware or software (i.e. perhaps once or twice a year). “It’s all about confidence and trust,” adds Mertens. “The water phantom will give the medical physicist peace of mind, ensuring that their MR/RT system is calibrated accurately for the verification of delivered dose to the patient.”

Beyond initial QA applications for MR/RT systems, LAP has released a version of the water phantom for the commissioning and QA of traditional bore-type linacs – specifically targeting clinical users of Varian’s Halcyon image-guided radiotherapy system and ETHOS, the vendor’s AI-enabled adaptive radiotherapy machine. “Alongside the original THALES 3D MR SCANNER,” concludes Mertens, “we have now launched the THALES 3D SCANNER. In the long term, this ‘two in one concept’ will allow more clinics and treatment centres to use the water phantom.”

- For further information, see the on-demand LAP webinars: Commissioning and QA workflows of MR-Linac with the THALES 3D MR SCANNER and User experience of MRIdian Linac commissioning and QA with the THALES 3D MR SCANNER.

What the customers say

Workflow automation, intuitive software for data collection and analysis, plus minimal training overhead: these are just some of the recurring themes from LAP customers who have deployed the THALES 3D MR SCANNER over the past 12 months to support their MR/RT commissioning and machine QA efforts.

For Thierry Gevaert, professor and head of medical physics at UZ Brussel (UZB), Vrije Universiteit Brussel (VUB) in Belgium, and an early-adopter of the LAP THALES 3D MR SCANNER, the priorities when choosing a water phantom are ease of use, straightforward software to perform the measurements, and the ability to incorporate different types of ion chambers. “The reason for this is that our water phantom is only used extensively during commissioning and thereafter just a few times a year,” he explains.

In this regard, it seems the LAP THALES 3D MR SCANNER ticks all the boxes for the commissioning and QA of UZB’s ViewRay MRIdian system. “With only one day of training, we were able to use the phantom’s software to rapidly perform all the necessary data collection,” adds Gevaert. “Moreover, being fully automated, we gained time during the commissioning testing procedure versus our traditional manual phantom.”

That headline take is echoed by Randa El Gawhary, a medical physicist at San Pietro Hospital FBF in Rome, Italy, where the LAP THALES 3D MR SCANNER is also being used for the characterization and QA of the clinic’s ViewRay MRIdian system. “We have been impressed with the LAP phantom from the very beginning,” she explains. “It is a reliable QA system with high-quality electronics, while the software allows a very smooth workflow for fast and accurate measurements.”