Researchers in Norway and Germany have shown that structural colouration can be easily created from clay suspensions. Due to the sustainability and abundance of clay minerals, this could lead to inexpensive structural colours that are environmentally friendly and non-toxic, with applications ranging from cosmetics and health to windows and tiles, they claim.

Most colours are created by the absorption of light by dyes and pigments. The colours we see are the wavelengths that are not absorbed and bounce back. Structural colours are different. They are produced by nanostructures that scatter and reflect light. Scientists are interested in creating structural colours as they could be more sustainable and durable than colours from dyes and pigments.

Due to the natural abundance, stability and low toxicity of clays, Jon Otto Fossum, a physicist at the Norwegian University of Science and Technology, and his colleagues wanted to see if they could be used to create structural colours. They started their research using the synthetic clay Na-fluorohectorite. When immersed in water, Na-fluorohectorite forms liquid crystal suspensions with single nanosheets of the mineral separated at a uniform distance from each other. This distance is linked to the concentration of the suspension – the ratio of water to Na-fluorohectorite.

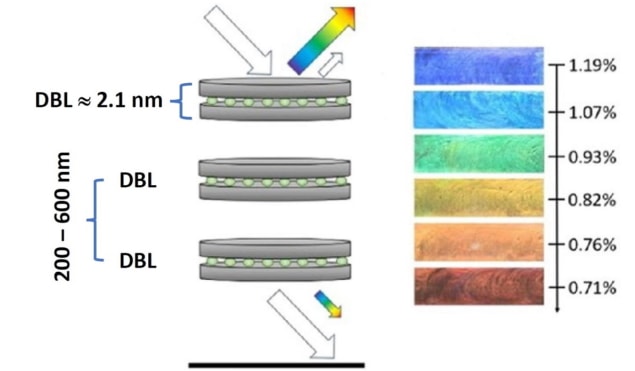

In their latest work, reported in Science Advances, the researchers demonstrate that the clay particles in these semi-transparent suspensions reflect light and produce colour. By adjusting the Na-fluorohectorite-to-water ratio, and therefore the distance between the nanosheets, they were able to tune the wavelengths of light reflected and the colours produced. While this generated colours covering the whole spectrum, they were not particularly bright.

To increase the brightness, the team turned to an interstratified – alternate layered – mixture of Na-fluorohectorite and caesium. When emersed in water, the Na-fluorohectorite again separated into nanosheets, but this time they formed double layers bound together by a thin layer of caesium. This quickly produced structural colouration that was much brighter than with the single sheets of Na-fluorohectorite, as the thicker double layers reflect more light.

“We can make clay nanosheets less transparent by making and using a double nanothin layer with an element between them,” says Fossum. “In this example, we used the element caesium, but other substances can also be used.”

The structural colours could be rapidly tuned by adding more water, the team found. The nanosheet spacing is controlled by electrostatic interactions, so it can also be changed by adjusting the ionic strength of the solution. When the researchers increased the salt concentration of a red double layer suspension, the colour shifted through yellow and green to blue. The increasing salt levels dampened the electrostatic forces between the layers and the separation distance decreased.

“The distance between the double clay layers is what produces the colour we see,” Fossum explains. “We can control that distance by means of the clay concentration or salt content in the material, such as water, that the clay is suspended in.”

Inkjet technique prints rainbow of structural colours from a single transparent ink

According to the researchers, the technique should also work with natural clays, such as vermiculite. They note that the clay can be suspended in other transparent materials besides water, including polymers or hydrogel matrices. Here, the clay nanosheets could provide additional benefits as they are known to improve the mechanical strength and stability of such materials. This could enable the development of composites from normally mechanically weak matrices with tunable structural colouration, mechanical strength and stability, the researchers claim.

Next, Fossum and his colleagues plan to test different matrices such as biobased polymers to create sustainable and biodegradable pigments. They add that by using responsive polymers they may also be able to create colours that can be changed by applying electric, magnetic or mechanical forces.