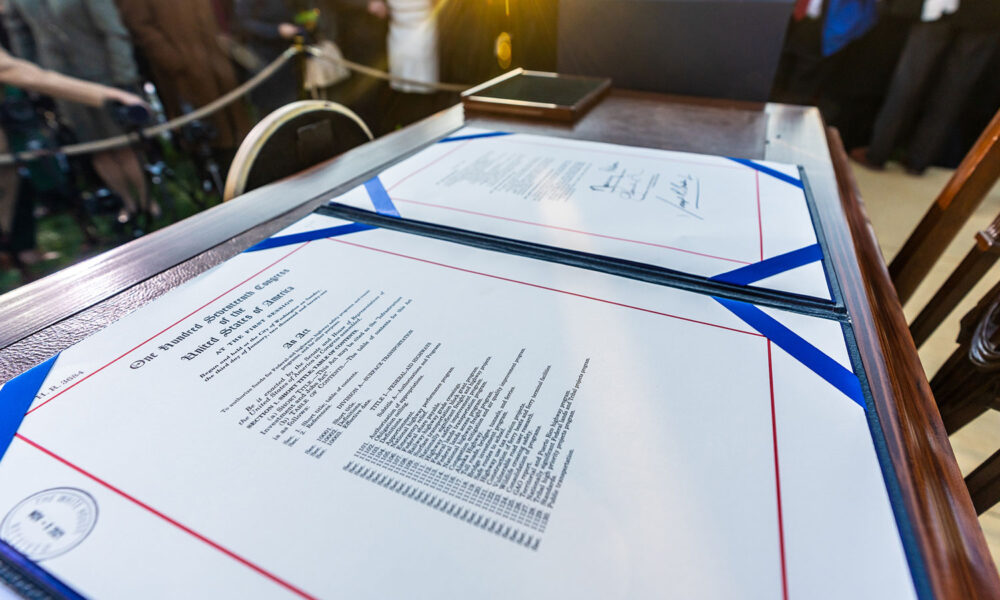

It’s been one year since passage of the Bipartisan Infrastructure Law (BIL), which included provisions to further clean transportation. Importantly, the BIL invests in electric vehicle (EV) battery recycling and repurposing– important strategies for increasing the sustainability of EVs.

The Department of Energy recently announced 10 recycling and repurposing projects that will receive a total of $73.9 million in funding. These projects could be key contributors to the technological innovation and scale up necessary to increase domestic recycling and make second-life stationary storage more accessible.

Currently, transportation is the largest contributor to climate-changing emissions. EVs can significantly reduce the sector’s emissions and set us on a path to reach our climate goals. While EVs deliver major climate emission benefits compared to gasoline vehicles, the recycling and reuse of EV batteries will help ensure the transition to EVs is sustainable over the long term.

Before recycling, batteries in good condition can be repurposed into a second-life application such as stationary storage. Second-life storage extends the lifespan of EV batteries while also helping decarbonization efforts– stationary storage is becoming more necessary as more of our electricity comes from renewable sources and as climate impacts threaten grid reliability. For example, storage is used to support solar photovoltaic systems by charging mid-day when the sun is strong and then discharging in the evening when energy demand peaks. In addition, California has begun exploring the option of using stationary storage as a backup resource when electricity is turned off to prevent wildfires.

When batteries reach the end of their life, they can all be recycled. The materials recovered can be used in the manufacturing of new batteries, resulting in large sustainability gains. The recycled materials replace the need for newly mined materials, therefore lessening the amount of mining necessary for the clean energy transition and creating a domestic supply.

These nascent industries are expanding rapidly and the Bipartisan Infrastructure Law investments are carefully aimed at addressing key challenges in repurposing, recycling, and the uptake of EVs.

What second-life projects were funded?

The Bipartisan Infrastructure Law funds went to five different second-life demonstration projects. The parties involved in these projects are wide ranging, including Universities, National labs, Utilities, auto manufacturers, well established companies, and startups.

Second-life demonstration projects include providing access to energy storage in underserved communities and EV charging in rural areas, as well as tech development that increases access to information and control over battery operations.

One project is aimed specifically at using these repurposed batteries to increase the accessibility of EV charging in rural areas. The stationary storage will be used as a charging station to provide more options for drivers to charge and provide relief from increased electricity demand on the grid. The effort will provide EV charging infrastructure in a multistate region (including Tennessee, Ohio, Virginia, Kentucky, West Virginia, Kansas, and Texas) and aide in the electrification of underserved rural communities.

Several of these projects are focused on technological improvements that will increase the efficiency and safety of second-life storage. Improvements begin with determining the battery health — this is a necessary estimation used for assessing if the battery is suitable for a second-life application. This estimation process is critical but lengthy. A second-life company received funding for technology that can drastically speed up the process, estimating the battery’s health in two minutes.

After the batteries have been tested and diagnosed as safe for repurposing, they are combined to make a larger storage system. This storage system is a mix of batteries with varying levels of capacity and the performance is restrained by the lowest performing cell. The charging and discharging of the cells are typically controlled in unison, restricting the capability of batteries and degrading them at a higher than preferable rate. Technology that enables more refined control of battery operations and knowledge of cell health was proposed in three of the five fund recipients. These innovations have the potential to increase the efficiency, lifespan, and safety of second-life storage.

What about battery recycling projects?

The other half of funded projects are focused on the development of recycling processes. Recycled materials have the potential to greatly decrease environmental and social impacts associated with batteries. Through their recycling and recovery, the need for newly mined materials can be reduced and the materials can continue to be used within the economy.

One recycling technique, called hydrometallurgical processing, has made great strides demonstrating high recovery rates of critical materials (think cobalt, nickel, manganese, and lithium) that can be used to manufacture new batteries. The technology is already operating at industrial scale and ready for expanded capacity. This funding will be used to continue improving this recycling process and build facilities in Nevada and Ohio.

The further development of a new recycling process, typically called direct cathode recovery, was also funded. This process recovers the battery materials in a form that is further along the manufacturing process. Essentially, instead of recovering the constituent materials like hydrometallurgical recycling does, direct recycling recovers these materials in their combined and processed form. The material recovered from using the direct cathode recovery process can more readily be reused, reducing the number of energy intensive steps in the manufacturing process.

A step in the right direction

This historic investment will greatly increase the repurposing and recycling innovation and infrastructure in the United States. It’s a necessary step in the direction towards a more circular, low impact, and domestic electric vehicle economy.