The first thermophotovoltaic cells with an efficiency of more than 40% – higher than any existing solid-state heat engine, and exceeding even the average efficiency of turbine-based power generation – have been fabricated by researchers at the Massachusetts Institute of Technology (MIT) and the US National Renewable Energy Laboratory (NREL). The cells, which are two-junction devices made from III-V semiconducting materials with electronic bandgaps between 1.0 and 1.4 eV, use back surface reflectors to divert unusable sub-bandgap radiation back to the source, and are optimized for heat sources at temperatures of 1900–2400 °C. According to their developers, the cells could be integrated into renewable energy systems for low-cost thermal grid storage.

Thermophotovoltaic (TPV) devices use photovoltaic cells to convert the predominantly infrared light emitted by hot objects (at 600 °C or more) into electrical energy. They can operate with higher-temperature heat sources than those used by turbines, and their range of possible sources is very broad, including combustion, nuclear reactions, waste heat, heat stored in a thermal energy storage system and solar radiation via an intermediate radiation absorber. All these sources are, in principle, more reliable than wind or solar energy generated directly from sunlight, both of which are intermittent.

New efficiency of 41.1%

The first TPVs were made from an integrated back surface reflector and a tungsten source emitting at 2000 °C. These devices had an efficiency of just 29%, and despite subsequent advances, TPVs have struggled to exceed the 32% mark and operate at temperatures below 1300 °C. The theory of TPVs, however, predicts that their efficiencies can exceed 50%, so researchers suspected there was room for improvement.

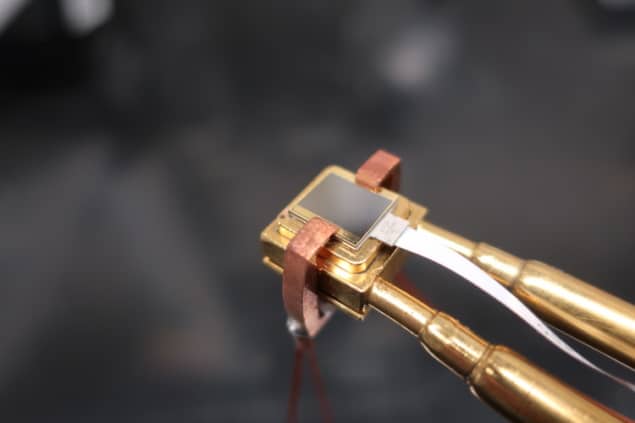

The new TPV cells, which were developed by a team led by Asegun Henry and Alina LaPotin of MIT’s Department of Mechanical Engineering, have a maximum efficiency of 41.1% and operate at a power density of 2.39 W/cm2 using a heat source emitting at 2400 °C. The devices were fabricated by researchers at the National Renewable Energy Lab (NREL) using a technique called organometallic vapour phase epitaxy.

The first of the team’s two cell designs uses top and bottom junctions made from AlGaInAs and GaInAs grown on a GaAs substrate. In this design, the AlGaInAs has a bandgap of 1.2 eV and the GaInAs a bandgap of 1.0 eV, and their lattices are mismatched with respect to the crystallographic lattice constant of the substrate. The second design combines a lattice-matched 1.4 eV GaAs top cell with a lattice-mismatched 1.2 eV GaInAs bottom cell.

The cells’ high efficiency comes from a combination of factors, LaPotin tells Physics World. “The first is the use of multi-junction cells that allow us to convert different energy bands of the incident spectrum more efficiently by reducing so-called thermalization losses,” she explains. “The second is the use of materials with a bandgap that is higher than those typically employed for TPVs, along with higher heat-source temperatures.”

“Usually, TPV targets bandgaps of around 0.7 eV with source temperatures lower than 1300 °C,” LaPontin continues. “Since there is an almost constant ‘penalty’ you pay on the voltage produced, moving to higher bandgaps (of 1.0 to 1.4 eV) confers an advantage. Indeed, as you move to higher bandgaps, you get higher voltage and the penalty becomes a smaller fraction of the total voltage, thereby leading to a higher overall efficiency.”

Other factors contributing to the device’s high efficiency include the use of a high-reflectance back surface reflector to send sub-bandgap radiation back to the heat source, as well as the high-quality fabrication techniques developed at NREL, LaPontin says.

More funding required

Henry says that the team’s device represents the first time that the efficiency of TPVs has reached 40% and the first time that any solid-state heat engine has ever demonstrated an efficiency higher than the average efficiency from turbine-based power generation in the US. The comparison to the average turbine is key, he says, because turbines currently have a near-monopoly on large-scale power production thanks to their low cost and efficiency. “This is the first time in history that another technology has shown a similar efficiency, lower cost and scalability, such that it can compete with turbine-based heat engines,” he says.

In Henry’s view, TPV technology merits more attention from the science and engineering community and “really deserves to get funding” for research and development. He notes that research into generating energy via an alternative method involving streams of supercritical CO2 has received around $100m in US government funding.

Solar cell keeps going after sunset

For their part, the MIT researchers have turned to developing thermal batteries that are compatible with their TPV technology, which Henry says could be “a huge part of the solution to mitigating climate change”. “Thermal batteries are an extremely low-cost, grid-scale energy storage technology that can enable full penetration of renewables onto the grid,” he explains. “The main applications for the cells we have demonstrated in our work is for these types of batteries.”

Another option for TPVs would be to combine them with hydrogen-fuel technology. “Some of the advantages of TPVs over turbines in this context include lower cost, faster response times, low maintenance, fuel flexibility and the ability to be cost effective at smaller power-generation scales – on the order of 10 MW,” Henry says.

The researchers now plan to test their cells in a thermal battery prototype system and pilot demonstration. They also hope to further improve the cells’ efficiency to 50% by increasing the fraction of unusable radiation they reflect to 97–98%.

The present work is detailed in Nature.