Guest Post by Mariel Price 2021-2022 Sustainability Leadership Fellow, and Ph.D. Candidate in the Department of Chemistry at Colorado State University

Every minute, one garbage truck worth of plastic is dumped into our ocean. Why is that a problem? Well, plastics were built to last. The reason why they are so useful is the same reason they pose a threat to life as we know it. When plastic waste accumulates in river systems, it can cause a jam that leads to the buildup of stagnant water (aka: a breeding ground for disease carrying insects). When plastic ends up in the ocean it can strangle unsuspecting wildlife, be eaten whole by marine animals, or be consumed in tiny pieces (microplastics) after it has been shredded by the forces of the ocean. It’s worth noting that these tiny pieces of plastics can eventually wind up on your dining table.

Do we have to choose between plastics and our health? Between plastics and the health of our oceans? Why is plastic waste so hard to manage? What solutions are emerging to stem the accumulation of plastic waste? How can you limit your consumption of plastic products and help increase the percentage of plastics being recycled? It might not surprise you to hear that there is no one answer to any of these questions. The reasons why we are now facing the prospect of having more plastic in the ocean than fish by the year 2050 are numerous, but thankfully, so are the emerging solutions to this problem.

It might sound like I am trash talking plastics, so don’t get me wrong—plastics are essential to modern life. Plastics are used to make cars lighter, faster, and safer. They are used to prolong the shelf life of foods. Clothing, electronic devices, medical devices, and numerous other technologies that make the world a better place exist because of the industrialization of plastic. Unfortunately, we have become overly reliant on this miracle material. We have figured out how to make plastics at such a low cost that their value to society and the threat of their accumulation has been disregarded while their production rate has exploded over the last 70 plus years.

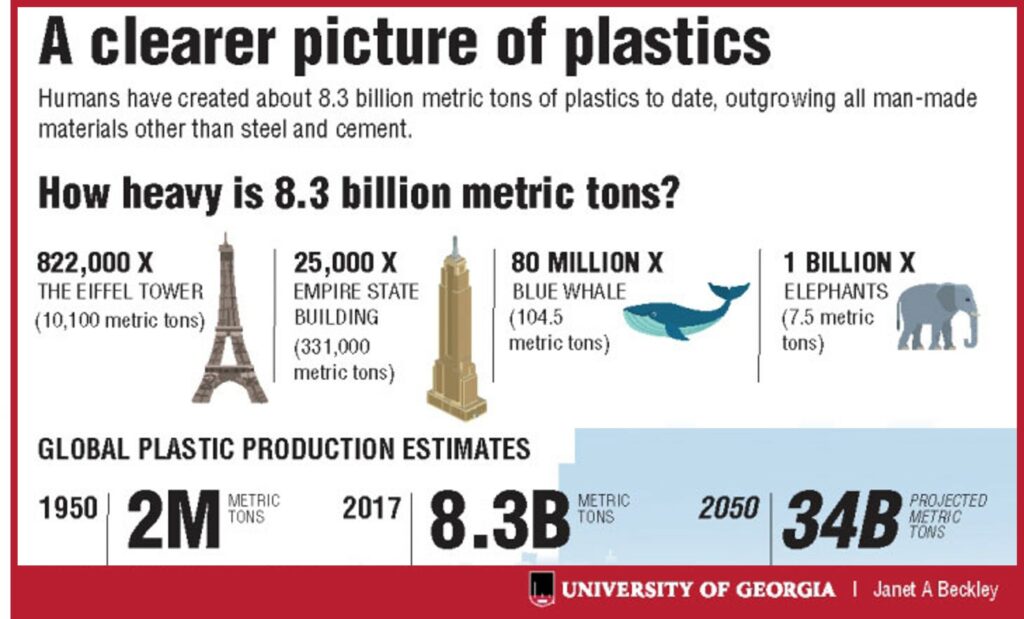

Between 1950 and 2015, humankind produced an estimated 8.3 billion metric tons of plastic and from that an estimated 6.3 billion metric tons of plastic waste. In case you, like me, have trouble picturing 8.3 billion metric tons, it’s about the mass of 25,000 empire state buildings (Figure 1). Of the 6.3 billion metric tons of plastic waste generated between 1950 and 2015, a mere 10% was recycled, 14% burned, and 76% discarded to landfills, dumps, or into the environment. The fact that only 10% of all the plastic waste ever generated has been recycled might make you feel like we just need to recycle more and then we can start to minimize the volumes of plastic waste clogging our landfills and ending up in the environment. Again, its not that simple. For one, it is just plain cheaper to make new plastic than to collect, wash, separate, and sell recycled plastic. Additionally, plastics are challenging to recycle even if they do end up at a recycling facility. In fact, most plastics only get one or two additional uses from recycling before then end up in a landfill (or in the environment).

Why can’t all plastics that end up at a recycling facility get recycled, forever? It comes down to the way that plastics are made, how they are used in products, and the infrastructure for recycling them.

First, not all plastics are created equal. The chemical structure of different plastics means that some can withstand the process of mechanical recycling where others cannot. Mechanical recycling involves grinding the plastic, melting it down, then remolding it into a useable form. Some types of plastic make it through this process intact and can be recycled, where others degrade and must be downcycled. The catch is, downcycled plastic is of such low quality that it isn’t likely to be recycled again into anything useful. A yogurt container may be able to live one more life mixed with other plastics to form the handle of a toothbrush, but after all the bristles have fallen out…off to the landfill.

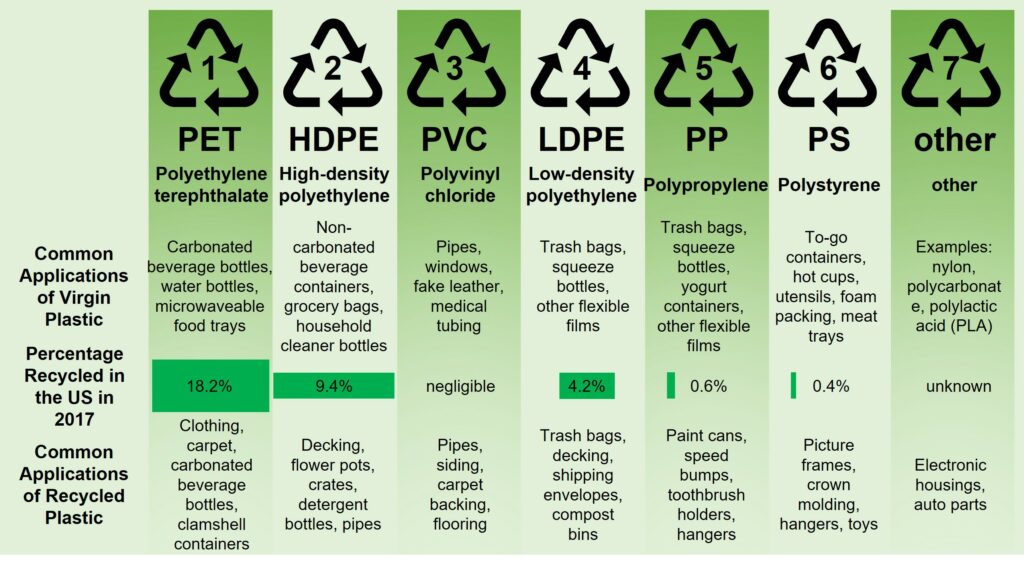

Second, the construction of plastic products can make recycling difficult. For plastics to be recycled effectively, each type of plastic needs to be separated. One might think that this is easy since each type of plastic is labeled with a different number (often located on the bottom of the container inside the chasing arrows recycling triangle) (Figure 2). Unfortunately, the way plastic products are made does not mean that one bottle labeled “#1” is identical to the next bottle labeled “#1” or that either of those is made purely from plastic resin #1 (also know as PET). The engineering of plastic products can get pretty complicated, but a good example is your average 2-liter plastic soda bottle. A plastic soda bottle labeled “#1” is actually composed of seven different types of plastics. That’s right, SEVEN. Additionally, additives like dyes, fire retardants, and adhesives can render plastics undesirable candidates for recycling. These additives make it so that one #1 PET bottle with different additives than another #1 PET bottle can’t be mixed during recycling to form a high quality and marketable product.

Third, contamination in recycling waste streams can make it hard to recycle plastics. The issue with contamination builds off my last point, but to make it clear all sources of contamination including things like residual food, grease, labels, and externally applied adhesives make it harder to recycle plastics. The contaminants can get mixed into the plastic when it is being ground and melted which changes the properties of the plastic and limits its applications as a recycled material. When people say that you should wash your containers before recycling them, this is why. For the most part, recycling facilities have the tools to wash contaminants like food off plastics, but it won’t hurt to soak your peanut butter container and give it a good wipe down before you put it in the bin. In the end, the food left over on your containers likely isn’t going to be the only reason why the plastic isn’t recycled, but hec, do the best you can…right?

The three points I made above may make it seem like the accumulation of plastics in the environment and our landfills is inevitable and impossible to overcome. Fortunately, there are emerging solutions designed to combat the limitations of our current plastic production and recycling system. The two types of solutions I think have the biggest potential to divert the flow of plastic waste from landfills and the oceans back into our economy are: infrastructure changes and alternatives to mechanical recycling as well as the advent of new and more sustainable plastics.

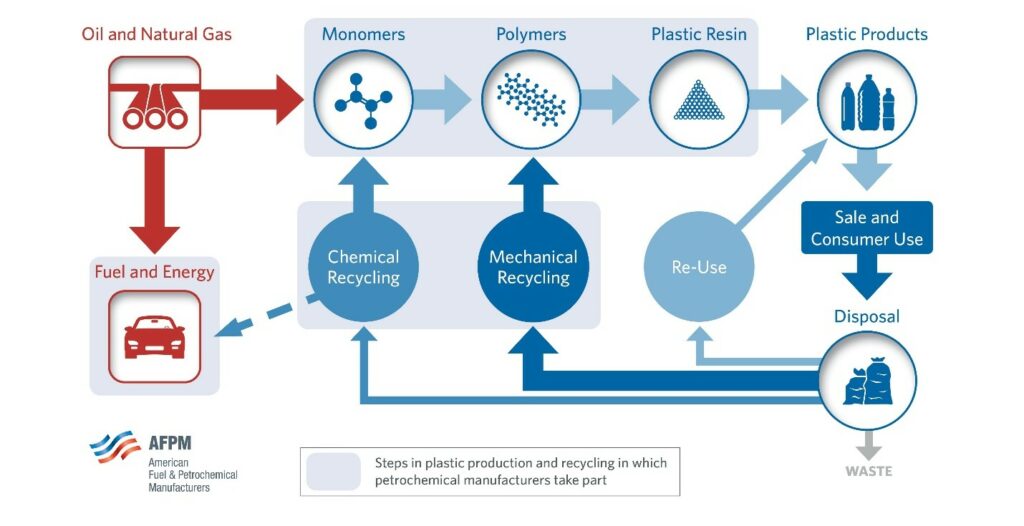

Supplements to traditional recycling: Mechanical recycling (the grinding, melting, and remolding of plastics) has its limitations as described above, but what if there was a way to extract the useful chemicals from a plastic to make new plastics or even other chemicals? There are dozens of companies that are starting to embrace techniques called “depolymerization” and “pyrolysis” both of which can be used to recover the useful chemicals from a plastic. These techniques enable access to a supply of chemicals that, once recovered from a plastic, can be used in fuel, petrochemicals, or in a new plastic. The bonus: both depolymerization and pyrolysis are claimed to be more tolerant to contamination that traditional mechanical recycling and can provide routes toward making virgin quality chemicals and materials from recycled plastic. For the chemical recycling of plastics to continue to serve as a compliment to mechanical recycling, the companies using this process need consistent suppliers of plastic waste and they need systems for collecting and transporting that waste. There has been a significant amount of growth in the infrastructure to support chemical recycling processes over the last decade and hopefully more to come.

Though chemical recycling has the benefit of being able to address the large volumes of plastic waste that already exist, it is not a one-stop-shop solution to all our problems. New types of bioderived, biodegradable, compostable, and chemically recyclable plastics are necessary to increase the sustainability with which we make, use, and dispose of plastics. Thankfully, some of these types of technologies are becoming more established and scientists and engineers in labs all over the world are working tirelessly to develop new and improved ones. The development of bioderived plastics is helping establish sustainable routes to plastics for when petroleum is no longer a viable source of chemicals for plastic production. But don’t be fooled, just because something is bioderived does not mean it can degrade in the environment or is any safer than traditional plastics. Biodegradable plastic alternatives, like the seaweed-based straws offered by Loliware can help ensure that when plastics end up in the environment they will safely decompose. There are a few compostable plastics on the market, the most common of which is PLA. A lot of dining services offer compostable PLA forks, however you can’t just throw these in your garden…they’re not readily biodegradable. In fact, it takes specific temperatures and soil conditions only found in designated composting facilities for PLA to readily decompose. Finally, I want to talk about my field of work: the intentional design of new chemically recyclable plastics. The intentional design of chemically recyclable plastics will give us access to a broader scope of materials that have the potential to be recycled an infinite number of times. Currently, there only two commodity plastics that can truly be deconstructed back their chemical building blocks via chemical recycling (PET and PS). The rest of the plastics that are being targeted for chemical recycling are converted into a soup of different chemicals that often require additional purification and separation before the can be used. At Colorado State University, both my lab, the Miyake Research Group, as well as the Chen Research Group are doing research to support the development of new, more sustainable alternatives to current plastics, including chemically recyclable plastics.

Though the rise of chemical recycling and the development of bioderived, biodegradable, compostable, and depolymerizable plastics are important solutions to the plastic waste accumulation crisis we are facing, I have really only touched the surface of how complicated the lifecycle of a plastic is and the variety of solutions that exist to overcome this challenge. Plastic recycling is an issue impacted by everything from infrastructure, chemistry, and engineering to policy, equity, and gender. The Geneva Environment Network has put together an extensive list of articles that provide more detail on these topics.

So, purchase those re-useable containers, beeswax food wraps, shampoo bars, laundry detergent sheets, and other products that don’t need to be packaged or sold in plastic. But don’t beat yourself up when you get takeout in a plastic container once a month or forget to bring a re-useable bag to the store. Be that person who digs though the recycling to rinse out the peanut butter container your roommate just put in the bin. Remove the labels on your used plastics. All these things can help increase the percentage of plastics that squeeze through the recycling process to live another life in consumer hands, but when it comes down to it, the downfalls of the plastic recycling system are not going to be solved by your bamboo toothbrush.

Resources:

Basic Guidelines for Recycling Plastics

Policy on Plastics: Center for International Environmental Law

Geneva Environment Network: Plastics and the Environment

The Alliance to End Plastic Waste

Sources:

Geyer, R., Jambeck, J., Law, K., Production, use, and fate of all plastics ever made, Science Advances, 2017, 7, 25-29.

Tullo, A., Patel, P., The Future of Plastic, C&EN: ACS Discovery Report, 2020.

Clean Seas: https://www.cleanseas.org/