Researchers in fields such as tissue engineering and biomedical device development are increasingly harnessing the countless applications that 3D printing of bioscaffolds has unlocked. However, most common 3D printing techniques use highly specific materials that require careful chemical tuning to be rendered functional for practical use. For instance, light-based techniques such as stereolithography or digital processing can create fantastic structures, but require specialized light-activated materials to operate. Extrusion printing is much more versatile in terms of the classes of materials that it can work with. However, the achievable structural complexity can be limited by the technique’s nozzle-based, layer-by-layer deposition process.

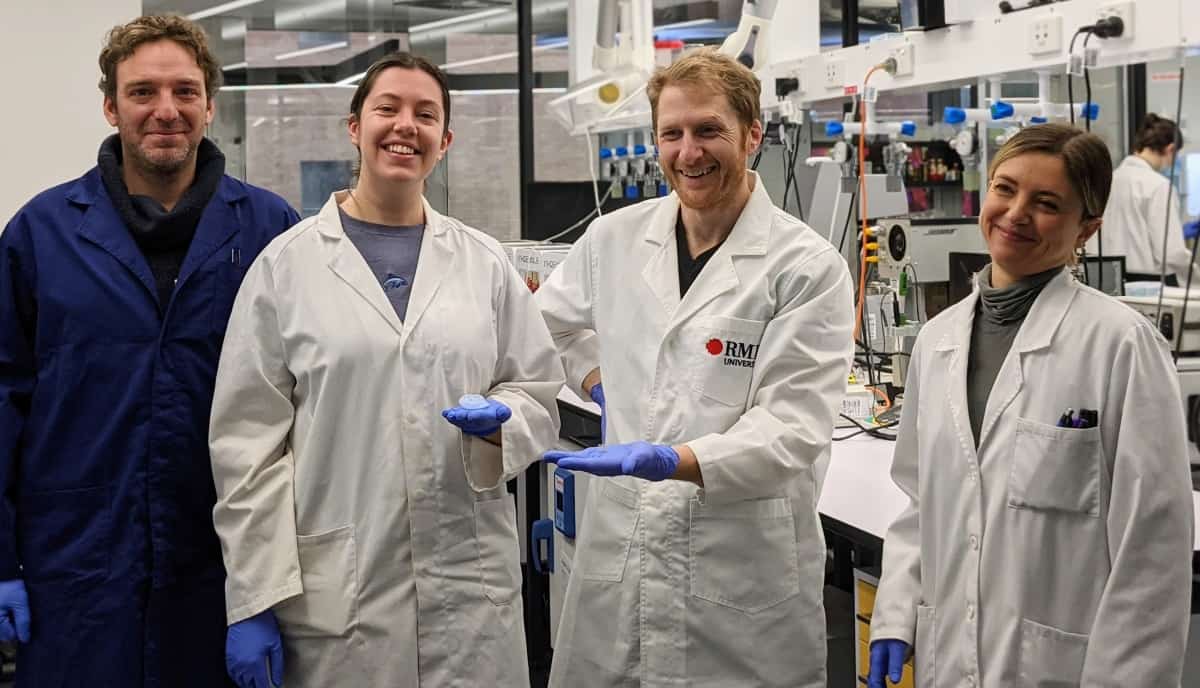

To overcome these limitations, a group of engineers and biomedical scientists in Australia has developed a new technique, termed “negative embodied sacrificial template 3D”, or NEST3D, printing. The researchers describe their approach in Advanced Materials Technologies.

A stand-out technique

The unique feature of this new 3D printing technique is that instead of making the bioscaffold directly, the researchers 3D print moulds with predefined, highly precise and intricate geometries, and then fill the cavities with biocompatible materials. The moulds are then dissolved away. This “indirect” printing approach is amenable to use with many types of materials, from biodegradable thermoplastics (such as polycaprolactone), to resins, silicones, ceramics, hydrogels and more.

Extrusion printing constrains the geometric complexity of a 3D printed structure, as the diameter of the printing nozzle limits the minimum feature size. In contrast, NEST3D printing achieved features of just 140 µm, less than half the size of the nozzle diameter.

“By flipping our thinking, we essentially draw the structure we want in empty space inside our 3D printed mould. This allows us to create the tiny, complex microstructure where cells will flourish,” says Cathal O’Connell from RMIT University, who led the development of this technique. “Although indirect printing has been around for many years, we believe this is the first clear demonstration that it can actually surpass what direct printing can do – especially in the achievable resolution and structural complexity.”

Versatile applications

The researchers at RMIT University came together with clinicians at St Vincent’s Hospital in Melbourne to address a clinical problem: the application of printed bioscaffolds in biomedical implants. “Our new method is so precise we are creating specialized bone and cartilage-growing microstructures in a single bioscaffold,” says O’Connell.

In addition, the NEST3D printing technique is easily scalable for use in other medical applications as it can create complex shapes using a basic 3D printer, such as the ones found in high schools.

First author Stephanie Doyle also realized that the new method was so robust that the researchers could rapidly test combinations of materials to identify those that were most effective for cell growth. As such, 3D printed bioscaffolds were created with a variety of porosity, stiffness, cyto- and bio-compatibility, using a wide range of material classes.

As a proof-of-concept demonstration, the team grew osteoblastic (bone) cells in NEST3D structures and observed that the cells indeed proliferated and infiltrated the scaffolds. Cell viability assays showed that the NEST3D scaffolds had no detectable cytotoxic effects on the biological cells.

The researchers conclude that NEST3D printing demonstrates several advantages in terms of the structural complexity and the resolution of the final objects. They are now working to improve the average processing times by casting many parts in parallel.